Cutting

Subsea Cutting Solutions

DECO Subsea is a global provider of machine‑based subsea cutting services. We design, build and operate a fleet of in‑house abrasive waterjet (AWJ) cutting systems for offshore decommissioning, renewables and heavy marine construction. Our ultra‑high‑pressure AWJ machines deliver blind cuts, sub‑bottom cuts and internal or external cuts on piles, conductors, caissons and monopiles, with diamond‑wire solutions available where required.

General cutting solutions

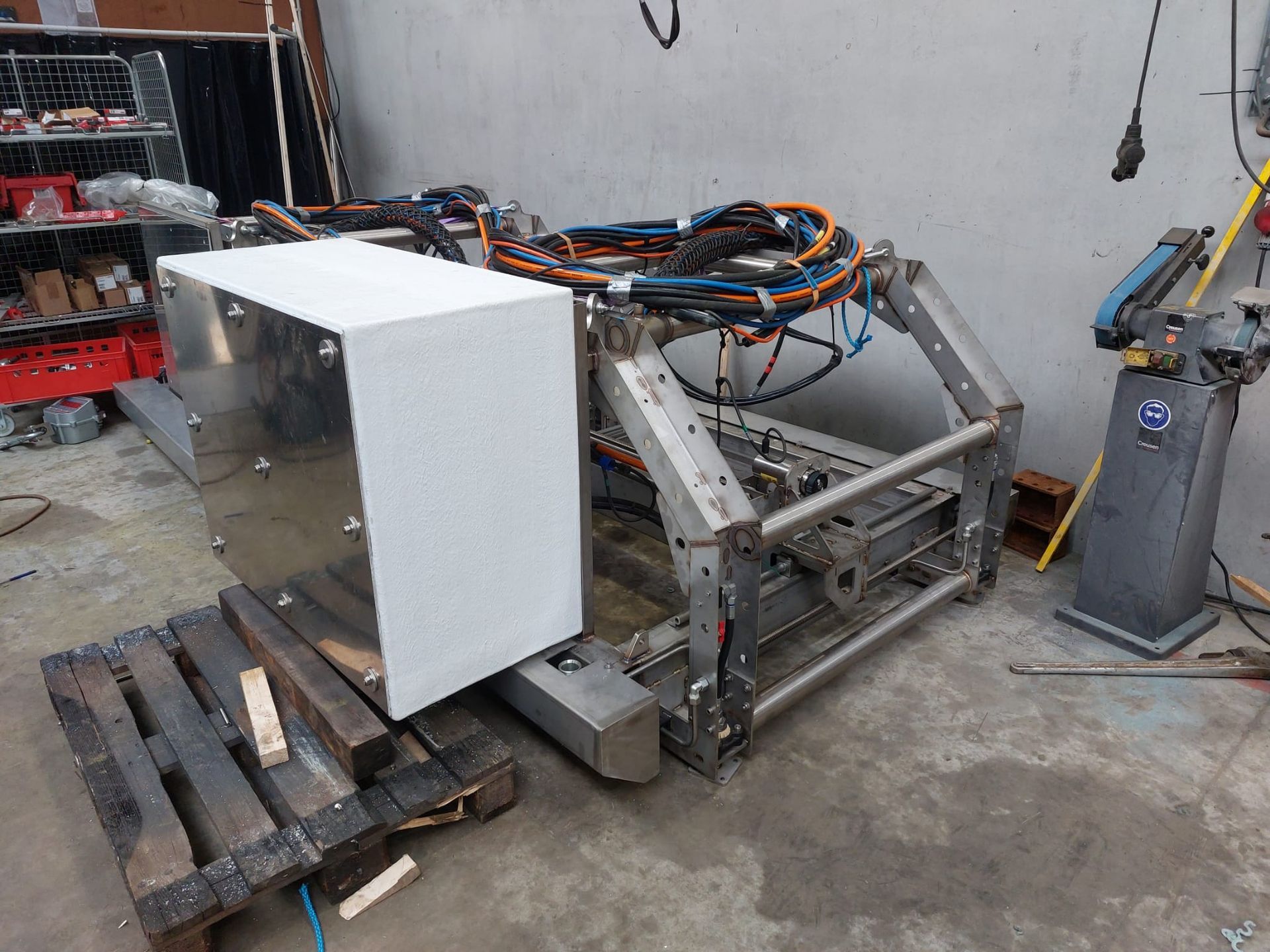

We engineer and implement cutting solutions tailored to each project. Our primary technology is ultra‑high‑pressure abrasive waterjet cutting, complemented by diamond‑wire or torch cutting systems where appropriate.

We develop project‑specific tools for external pile cutting, rack‑and‑pinion cutting, access cuts in hulls or structures, cold cuts for welding preparation and blind cutting of concrete and steel.

All cutting frames, robots and systems can be adapted for quay walls, topsides and subsea structures, with remote‑controlled or ROV‑compatible options that minimise or eliminate diver exposure and maximise repeatability. Most are available with various remote control and automation options that make them suitable for topside control, shallow water diver control or ROV control.

Pile cutting

Internal pile cutting is often the preferred solution for offshore oil & gas and wind turbine foundations, both during installation and decommissioning. DECO Subsea’s internal cutting tools use our patented ultra‑high‑pressure abrasive waterjet technology, developed and refined over more than two decades.

External AWJ pile cutting is somewhat less common but occurs on a regular basis.

Our systems provide class‑leading cutting power, speed and reliability, cutting in a single pass through heavy‑wall steel, cast iron, reinforced concrete and multi‑string conductors. With more than 1,800 piles cut at water depths up to 170 m, we offer tools for internal diameters from 550 mm to 3,000 mm, with a full 5m - 11m design ready for construction for the future large-diameter monopile decommissioning.

Internal AWJ tools can be combined with customised pile clamp and lifting arrangements, allowing cut and lift operations to be completed in a single controlled crane lift and enabling blind and sub‑bottom cuts where required.

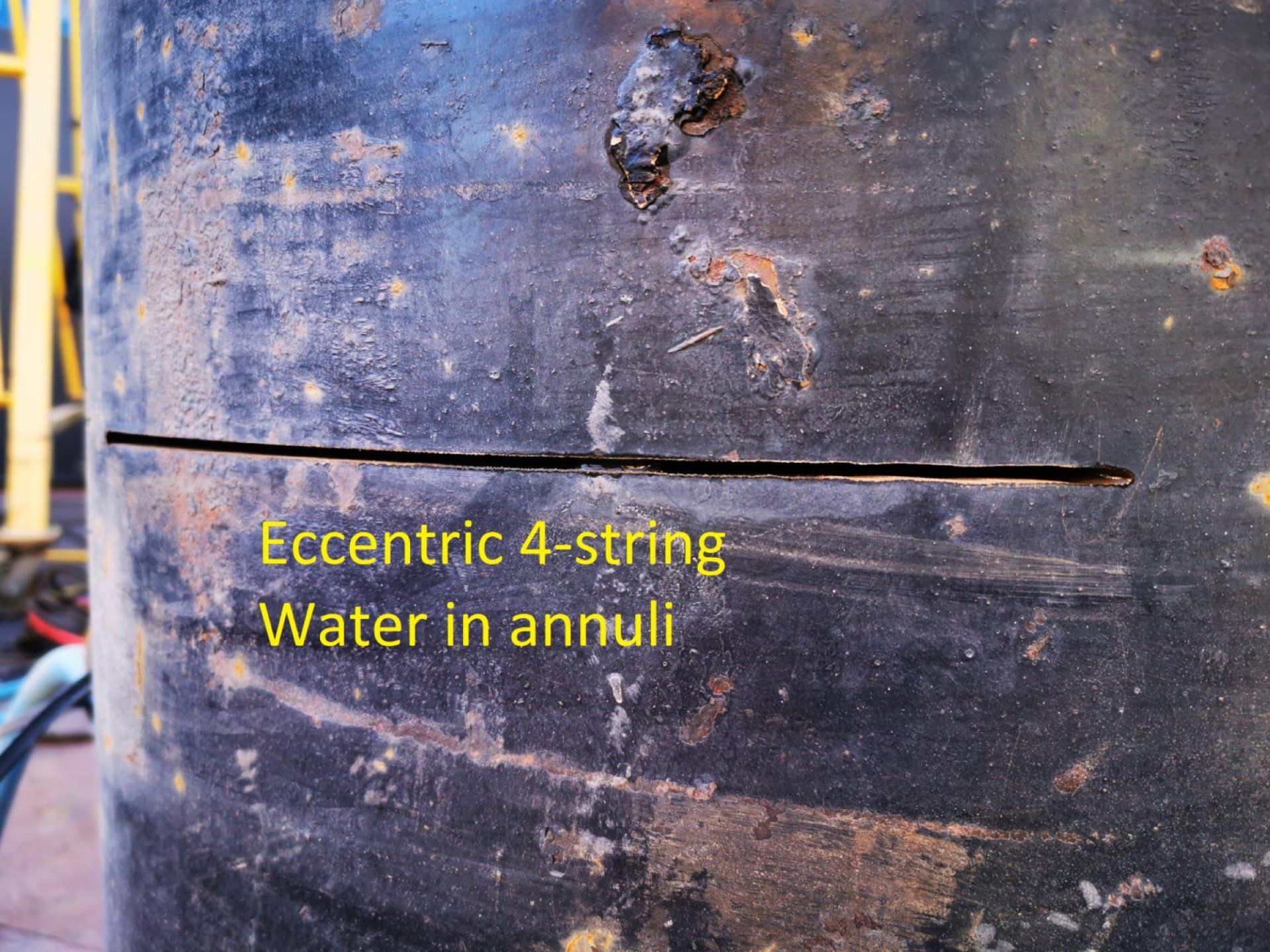

Multi-string conductor cutting

Conductor and casing removal is a critical element of well plug and abandonment (P&A). DECO Subsea’s in‑house–designed conductor cutting tools allow safe, efficient cutting of multi‑string conductors using the same proven UHP abrasive waterjet technology as our pile‑cutting systems.

Our tools are capable of single‑pass cuts through heavy‑wall steel, cast iron, reinforced concrete and multi‑string configurations, with a strong track record at water depths up to 170 m. Internal and external configurations are available to support platform, subsea and slot‑recovery campaigns in the North Sea and worldwide.

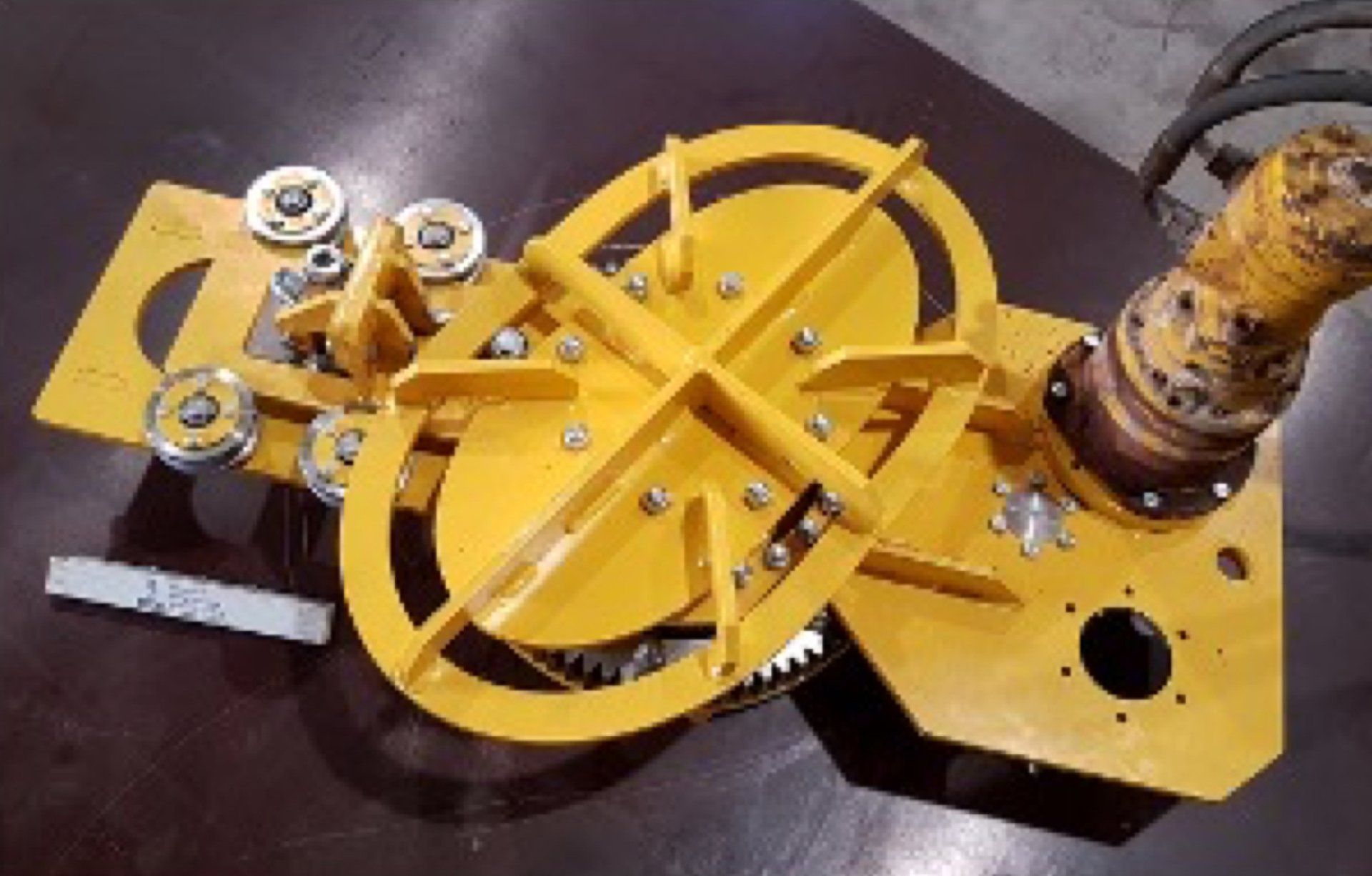

Hole cutting

DECO Subsea designs, builds and operates a wide range of hole cutting tools based on it's patented ultra-high pressure abrasive water jet subsea cutting technology. The standard range of hole cutting tools can be used to cut circular holes, elliptical holes or X-Y windows (i.e. square or rectangular holes) but in principle any shape is possible.

To date DECO Subsea has cut over 1200 holes for applications ranging from water replenishment, drainage and cable entry holes to shackle and

trunnion holes. Depending on the application, these holes were cut during installation, operation or decommissioning phase of offshore windfarms, oil & gas structures and ship wreck removal.